-

Painel de sanduíche de Rockwool

-

Painel sanduíche de poliuretano

-

Painel de sanduíche acústico

-

Painel de sanduíche do Glasswool

-

Armazém de aço da casa pré-fabricada

-

Painéis de revestimento do metal

-

folha de metal perfurada

-

Chapa de aço perfilada

-

Decking do piso de aço

-

painel de sanduíche de alumínio

-

Casa dobrável do recipiente

-

painel sanduíche EPS

-

Painel de sanduíche decorativo

-

Canto do painel de sanduíche

-

Bobina da chapa de aço

-

isolação das lãs de vidro

-

isolação do rockwool

-

Viga de aço estrutural

-

Ângulo de aço

-

Secção do canal de aço

-

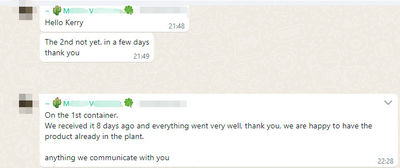

SENHOR“Nós recebemo-lo 8 dias há e tudo foi muito bem agradecer-lhe que nós estamos felizes ter produto já na planta. Qualquer coisa que nós nos comunicamos com você”

SENHOR“Nós recebemo-lo 8 dias há e tudo foi muito bem agradecer-lhe que nós estamos felizes ter produto já na planta. Qualquer coisa que nós nos comunicamos com você” -

SENHOR“Olá! Kerry, nós fizemos alguns testes mais adicionais no painel e nós estamos felizes com os resultados.”

SENHOR“Olá! Kerry, nós fizemos alguns testes mais adicionais no painel e nós estamos felizes com os resultados.” -

Sra.muito satisfeita e bom produto. envio rápido e tudo correu muito bem

Sra.muito satisfeita e bom produto. envio rápido e tudo correu muito bem

Estrutura de aço de alta qualidade de grande extensão, construção de armazém pré-fabricado, oficina pré-fabricada, design moderno, instalação rápida

| Lugar de origem | Hebei,China |

|---|---|

| Marca | BAODU |

| Certificação | ISO9001,CE |

| Número do modelo | Armazém de Aço |

| Documento | Folheto PDF do produto |

| Quantidade de ordem mínima | Discutível |

| Preço | Reasonable |

| Detalhes da embalagem | Em geral, para estrutura de aço, utilizamos a embalagem da estrutura de aço para evitar que a mercad |

| Tempo de entrega | 15-21Days |

| Termos de pagamento | L/C,D/A,D/P,T/T,Western Union,MoneyGram |

| Habilidade da fonte | 10000 metros quadrados/metros quadrados por mês |

| Nome do produto | Estrutura de aço de alta qualidade de grande extensão, construção de armazém pré-fabricado, oficina | Palavra-chave | Armazém da construção da construção de aço |

|---|---|---|---|

| Serviço pós-venda | Suporte Técnico On-line | Material | Q235/Q345 AÇO |

| Estrutura | Estrutura de aço soldada | Revestimento do telhado | EPS/Rockwool/Fiberglass Wool/PU Sandwich Panel ou Chapa de aço |

| Serviço de processamento | Dobragem, SOLDAGEM, Desbobinamento, Corte, PERFURAÇÃO | Nome do produto | Armazém de aço pré-fabricado |

| Tamanho | De acordo com a exigência do cliente | Guia de instalação | Desenhos de instalação e vídeo |

| Vida | Mais de 50 anos | Tempo de instalação | 2-4 SEMANAS |

| Transportabilidade | Facilmente transportado por caminhão ou navio | ||

| Destacar | Armazém de aço pré-fabricado de grande porte,edifício de oficina pré-fabricado design moderno,Armazém de estruturas de aço de instalação rápida |

||

HI, querido amigo, por favor note que as estruturas de aço são projetadas sob medida para atender às suas necessidades específicas.A nossa equipa com mais de 20 anos de experiência irá criar o desenho exato, citação, e renderização com base em seus dados de construção ou desenhos.

- Colunas: de aço laminado a quente com secção H ou secções de caixas soldadas para suporte vertical

- Traças: traças H ou I que se estendem entre colunas

- Estruturas para telhados: Estruturas ou estruturas de secção C/Z para suportar a cobertura do telhado

- Cintas de parede: elementos horizontais que suportam revestimentos de parede

- Revestimento de telhados e paredes: chapas de aço ondulado, painéis sandwich isolados

- Sistemas de travagem: barras ou cabos de aço diagonais para estabilidade contra vento e terremotos

Bolinhos de alta resistência e soldagem garantem conexões robustas e integradas da estrutura.

Forneça as seguintes informações para um orçamento e um desenho personalizados:

- LocalizaçãoPaís e cidade onde o edifício será construído

- Tamanho:Comprimento × Largura × Altura das hastes (mm)

- Carga de vento:Velocidade máxima do vento (kn/m2, km/h ou m/s)

- Carga de neve:Altura máxima da neve (kn/m2, mm) e faixa de temperatura

- Resistência a terremotos:Nível sísmico exigido

- Parede de tijolos:Altura exigida (1,2 m, 1,5 m ou outra)

- Isolamento térmico:EPS, lã de fibra de vidro, lã de rocha, painéis sandwich PU ou chapas metálicas

- Portas:Quantidade e dimensões (largura × altura em mm)

- Janela:Quantidade e dimensões (largura × altura em mm)

- Grão:Quantidade, peso máximo de elevação (toneladas) e altura de elevação (m)

- Desenho de grande comprimento:Espaço interno aberto para armazenagem e equipamento de grande porte

- Construção rápida:Componentes pré-fabricados reduzem o ciclo de construção

- Peso leve:Redução das cargas das fundações e dos custos de construção

- Excelente desempenho sísmico:Segurança superior em condições extremas

- Durabilidade:A protecção contra a corrosão garante uma longa vida útil

- Alta flexibilidade:Desenhos personalizáveis para diferentes utilizações

- Amizade com o ambiente:O aço reciclável alinha-se com a sustentabilidade

- Baixa manutenção:Manutenção simples com baixos custos a longo prazo

- Projeto e Engenharia:Desenhos arquitetónicos e estruturais pormenorizados com cálculos de carga

- Fabricação:Cortar, soldar e perfurar componentes em ambiente de fábrica

- Preparação do local e fundação:Escavação e colagem de fundações de concreto

- Erecção:Montagem de estruturas de aço primário e de elementos secundários

- Revestimento:Instalação de telhados, revestimentos de paredes e sistemas de isolamento

- Finalização:Adicionar portas, janelas, ventilação e acabamentos interiores

Os nossos componentes pré-fabricados de aço são cuidadosamente embalados com embalagem segura e paletização para evitar danos durante o transporte.

Oferecemos envio mundial com custos variando de acordo com o destino e a quantidade da encomenda. Entre em contato com o nosso serviço de atendimento ao cliente para obter cotações de envio e prazos de entrega.

A Baodu International Advanced Construction Material Co., Ltd, estabelecida em 2010, com escritórios em Pequim e fábrica em Hebei, China, é um projeto, fabricante, fornecedor e fabricante global de materiais de construção avançados.e exportador de tratamento de ruído industrial, estruturas de aço, painéis sandwich e casas pré-fabricadas.

A capacidade de produção anual inclui 6 milhões de metros quadrados de painéis sandwich acústicos, 100 000 toneladas de estruturas de aço e 1 milhão de metros quadrados de chapa de piso,servindo em mais de 30 países em todo o mundo.

A nossa equipa de design profissional inclui 5 engenheiros seniores, 20 engenheiros e 35 técnicos com mais de 10 anos de experiência.qualificações em construção, certificação CE, e certificação russa GOST.

Projetos notáveis incluem a aldeia de desfile militar do 60o aniversário da China, o Aeroporto Internacional de Beijing Daxing, a usina de carvão Thar Pakistan e a usina de energia Hasyan Dubai.